Ice machines are essential for many businesses and homes. They provide a steady supply of ice for drinks and food preservation. But like any appliance, they need regular care to function well.

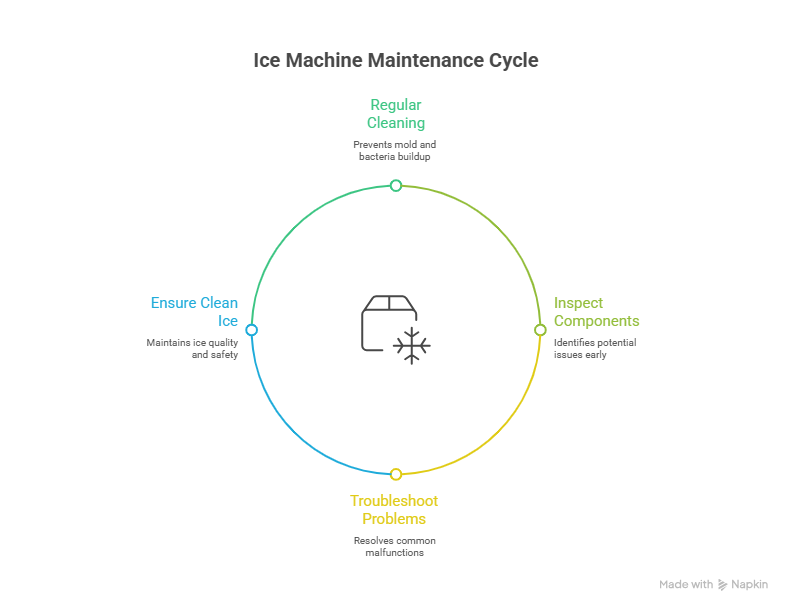

Proper maintenance can prevent costly repairs and extend the life of your machine. It also ensures the ice produced is clean and safe to use. Neglecting maintenance can lead to issues like mold, bacteria buildup, and reduced efficiency.

This guide will provide essential tips for maintaining your ice machine. You’ll learn about cleaning, inspecting, and troubleshooting common problems. Whether you own a commercial unit or a home ice maker, these tips will help keep your machine running smoothly.

Why Ice Machine Maintenance Matters

Ice machine maintenance is crucial for several reasons. First, it ensures the safety of the ice produced. A poorly maintained machine can harbor bacteria and mold, posing health risks.

Regular maintenance also improves the efficiency of the machine. When parts are clean and in good condition, the machine uses less energy. This efficiency translates into cost savings on utility bills over time.

Neglecting maintenance can lead to significant breakdowns. Consider the potential downtime without a working ice machine. By keeping your machine in top shape, you can avoid unexpected repairs.

Here are key reasons why maintenance matters:

- Ensures ice quality and safety

- Enhances machine efficiency

- Prevents costly downtime

Investing in regular maintenance keeps your ice machine reliable and prolongs its operational life. It’s a small effort with big rewards.

Top Tips to Choose the Best Ice Machine Repair Service

Types of Ice Machines and Their Maintenance Needs

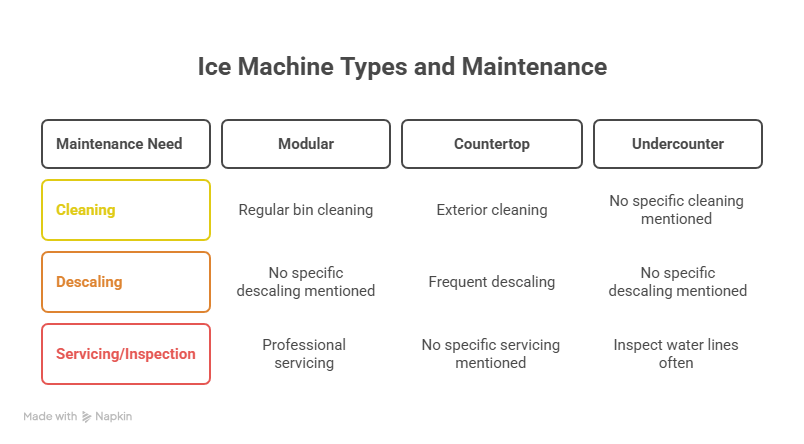

Ice machines come in various types, each with unique maintenance requirements. Understanding these differences is key to effective upkeep. For example, a commercial unit will have different demands compared to a home ice maker.

Each type may need specific care routines. For instance, modular units often require thorough cleaning of both the machine and the bin. Similarly, countertop ice makers may need frequent descaling due to their compact design.

Here’s a brief look at common types and their needs:

- Modular Ice Machines: Regular bin cleaning and professional servicing

- Countertop Ice Makers: Frequent descaling and exterior cleaning

- Undercounter Ice Machines: Inspect water lines often for leaks

Ensure you consult your machine’s manual for precise guidelines. Catering to the specific needs of your ice machine type can ensure it runs efficiently and lasts longer.

Daily, Weekly, and Monthly Maintenance Checklist

Regular maintenance is crucial for keeping ice machines running smoothly. A structured checklist ensures you don’t miss essential tasks.

Daily Tasks:

Keeping up with daily tasks helps avoid issues:

- Wipe down the exterior to prevent dust buildup.

- Check that the machine is level to prevent malfunctions.

- Clear any surrounding clutter for proper airflow.

Weekly Tasks:

Weekly maintenance allows for a deeper check:

- Inspect the water supply line for any leaks or kinks.

- Clean and sanitize the ice bin to prevent contamination.

- Monitor ice production rates for any unusual changes.

Monthly Tasks:

Monthly tasks focus on detailed maintenance:

- Remove mineral deposits with a recommended descaler.

- Inspect the condenser coils and clean if necessary.

- Ensure all parts are intact and functioning correctly.

Following this checklist can prevent major issues from arising. It reduces the risk of costly repairs and downtime. Regular maintenance maintains efficiency and extends the machine’s lifespan. By staying vigilant, you can ensure reliable ice production. Each task is simple but essential to your machine’s health.

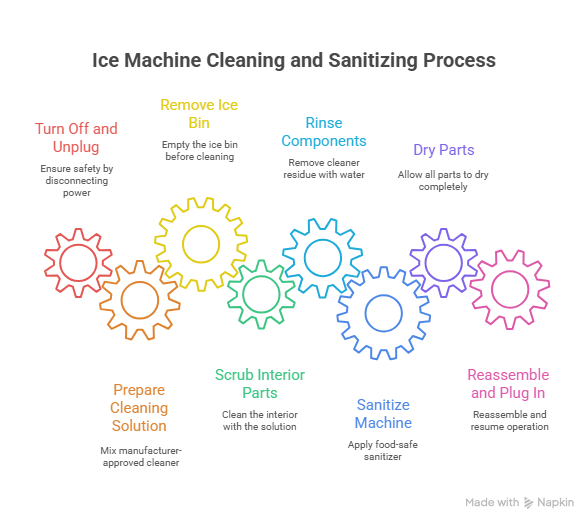

Step-by-Step Guide to Cleaning and Sanitizing Your Ice Machine

Cleaning your ice machine is a crucial task that prevents mold and bacteria buildup. Proper cleaning also ensures the efficiency of your machine.

Begin by turning off the machine and unplugging it. Safety should be your primary concern during any maintenance task.

Prepare a cleaning solution using a manufacturer-approved cleaner. Avoid harsh chemicals that could damage the machine’s components.

Cleaning Steps:

- Remove and empty the ice bin before cleaning.

- Use the cleaning solution to scrub the interior parts.

- Rinse the components thoroughly to remove any cleaner residue.

After cleaning, sanitize the machine to kill any lingering bacteria. Use a food-safe sanitizer and follow the instructions carefully.

Finally, allow all parts to dry completely before reassembling. Once dried, you can plug in the machine and resume operation.

Regular cleaning and sanitizing extend the lifespan of your ice machine. It keeps ice production sanitary and reduces health risks. Keeping a consistent schedule for these tasks is essential for optimal performance.

How to Inspect and Replace Water Filters

Water filters play a vital role in maintaining ice quality and machine longevity. Inspecting them regularly prevents unwanted debris and impurities.

Start by turning off the water supply to the ice machine. This is an important step to avoid leaks during filter replacement.

Remove the old filter carefully, observing the direction for the new one. Proper installation is crucial for effective filtration.

Filter Replacement Steps:

- Check your manual for specific filter types.

- Follow the installation instructions for the new filter.

- Turn the water back on and check for leaks.

Remember to replace filters every six months or as recommended by the manufacturer. This maintenance keeps your machine in optimal condition. Consistent attention to filter health aids in efficient operation and quality ice production.

Checking and Cleaning Condenser Coils

Condenser coils are integral for effective cooling. Dust and dirt can accumulate, affecting efficiency.

Ensure the machine is unplugged before starting to clean. Safety is the priority before handling components.

Use a soft brush or vacuum to remove debris from the coils. This method is gentle yet effective.

Coil Maintenance Checklist:

- Unplug the ice machine first.

- Locate and access the condenser coils.

- Use appropriate tools for cleaning.

Keeping coils clean prevents overheating and promotes energy efficiency. Regular maintenance guards against frequent breakdowns. Your ice machine will operate smoothly with these routine checks.

Monitoring Ice Production and Quality

Regularly checking your ice machine’s output is crucial. It helps identify issues before they become major problems.

Look for changes in the size, shape, or clarity of the ice. Such changes can signal underlying issues.

Keep a log of production rates and spot trends. Noticing gradual changes can help in diagnosing problems early.

Production Monitoring Checklist:

- Note any changes in ice appearance.

- Record daily production levels.

- Watch for delays in ice making.

Monitoring these aspects ensures your ice machine performs at its best. Early detection of issues can prevent expensive repairs down the line.

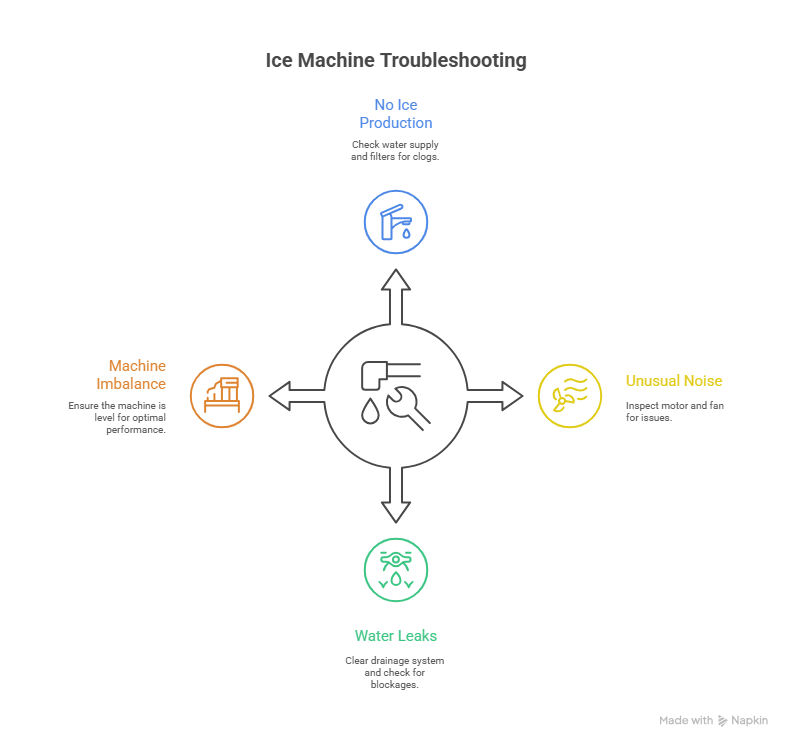

Common Ice Machine Issues and Troubleshooting Tips

Ice machines can face a variety of problems. Recognizing these issues early can save time and money.

One common issue is the machine not making ice. Check the water supply and ensure filters aren’t clogged.

Another problem is unusual noise. This may indicate problems with the motor or fan.

Leaking water is also a frequent issue. Ensure the drainage system is clear and check for any blockages.

Troubleshooting Checklist:

- Verify water supply connections.

- Listen for unfamiliar sounds.

- Inspect for visible leaks.

- Confirm the machine is level.

By regularly addressing these areas, you can maintain optimal performance. Troubleshooting minor problems promptly prevents them from escalating. Always refer to the machine’s manual for specific guidance.

Is It Worth It to Repair a Refrigerator? Complete Guide

When to Call a Professional: Ice Machine Repair and Service

Sometimes, ice machine issues require a professional touch. Recognizing these situations is crucial for effective maintenance.

Persistent leaks or electrical issues are best left to experts. Handling these alone can be risky and complex.

If your machine produces subpar ice despite routine cleaning, seek professional help. Experts can diagnose less obvious problems.

Routine maintenance by a professional is also recommended. This ensures the machine operates at peak efficiency.

Reasons to Call a Professional:

- Electrical malfunctions

- Consistent water leakage

- Reduced ice quality

- Strange, recurrent noises

Using a professional service guarantees thorough repairs and maintenance. They have the tools and experience to handle intricate problems. Timely intervention by professionals prevents costly future damages. Avoid trying to fix complex issues alone to ensure safety and performance.

Choosing the Right Ice Machine Service Company Near You

Selecting the right service company is vital for ice machine upkeep. A good company ensures efficient repairs and maintenance.

Begin by researching local service providers. Check reviews and ratings to gauge their reputation and reliability.

Discuss your specific needs and get detailed quotes. Choose a company that offers comprehensive services and competitive pricing.

Factors to Consider:

- Positive customer feedback

- Certifications and experience

- Availability of emergency services

- Transparent pricing and quotes

Choose a service with certified technicians for quality assurance. Personalized service ensures they meet your machine’s unique requirements. Opt for companies that offer routine maintenance plans to prolong your machine’s life.

Pro Tips for Extending the Life of Your Ice Machine

Maintaining your ice machine is not just about repairs. It’s about adopting habits that promote longevity.

Consistent maintenance routines help. Address minor issues before they escalate into costly repairs.

Additional Tips:

- Regularly clean and sanitize.

- Keep the machine in a well-ventilated space.

- Replace water filters as recommended.

- Use approved cleaning solutions.

Simple practices can significantly impact the machine’s lifespan. Stay proactive in addressing maintenance, and your machine will serve you well for years.

Conclusion: Keep Your Ice Machine Running Smoothly

Proper maintenance of your ice machine is crucial for seamless operation. Consistency in cleaning and regular check-ups ensures its efficiency. Addressing minor issues before they worsen saves time and costs.

By following essential tips and staying proactive, your ice machine will remain reliable. Whether for business or personal use, a well-maintained machine is a valuable asset. Prioritize routine care to avoid downtime and enjoy consistent, quality ice production.